style="font-size:16px;color:#1F2329;font-family:Inter, -apple-system, BlinkMacSystemFont, " background-color:#ffffff;"="">

From the perspective of material and craftsmanship, the quality foundation of StarLock push-type fasteners stems from the perfect combination of high-quality high-carbon steel and a specialized heat treatment process. The high-carbon steel used inherently possesses excellent strength and toughness, enabling it to withstand common loads and impacts in industrial scenarios. After undergoing customized specialized heat treatment, the fasteners see further improvements in hardness and wear resistance. This not only ensures stable clamping quality during long-term use, preventing loosening or failure caused by material fatigue, but also allows adaptation to temperature changes under different working conditions—even in environments with alternating high and low temperatures, the fasteners can maintain good structural stability. Such strict material and craftsmanship standards lay a solid foundation for the reliable performance of the fasteners, enabling them to demonstrate excellent adaptability in industries such as automotive, machinery, and electronics, where strict strength requirements are imposed on components.

Ease of installation is a core highlight of StarLock push-type fasteners, and this is particularly evident in the design of star-shaped locking fasteners, which fully embodies the concept of "efficiency and simplification". Unlike traditional fasteners that require complex thread processing and grooving operations, StarLock star-shaped locking fasteners only need to be gently pushed onto the shaft to instantly complete fixing and clamping. The entire process requires no additional tool support and no tedious processing of the shaft. This design not only eliminates the costly thread processing and grooving expenses but also significantly shortens assembly time. Taking the fixing of small motor shafts as an example, the installation of traditional circlips requires first grooving the shaft and then using special tools to embed the circlip, taking approximately 5 minutes in total. In contrast, with StarLock star-shaped locking fasteners, a single person can complete the fixing in just 10 seconds, increasing efficiency by nearly 30 times. More notably, once fixed in place, the star-shaped locking fasteners form an extremely strong stable effect that cannot be removed without damaging the components. This effectively prevents the loosening of fasteners caused by vibration during equipment operation, providing guarantee for the long-term stable operation of equipment.

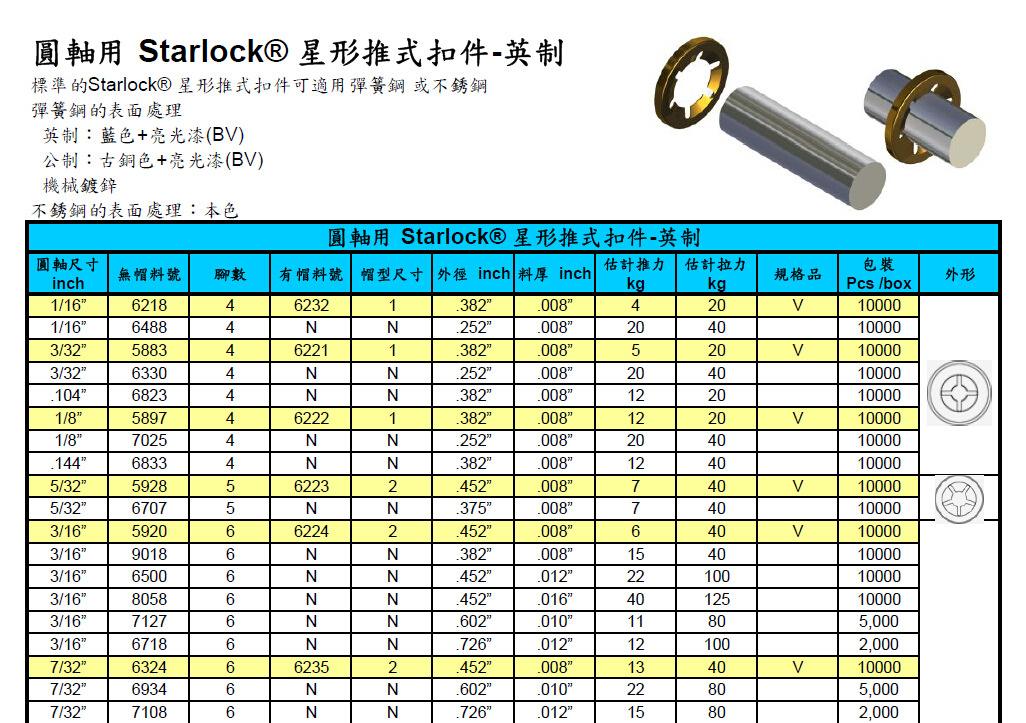

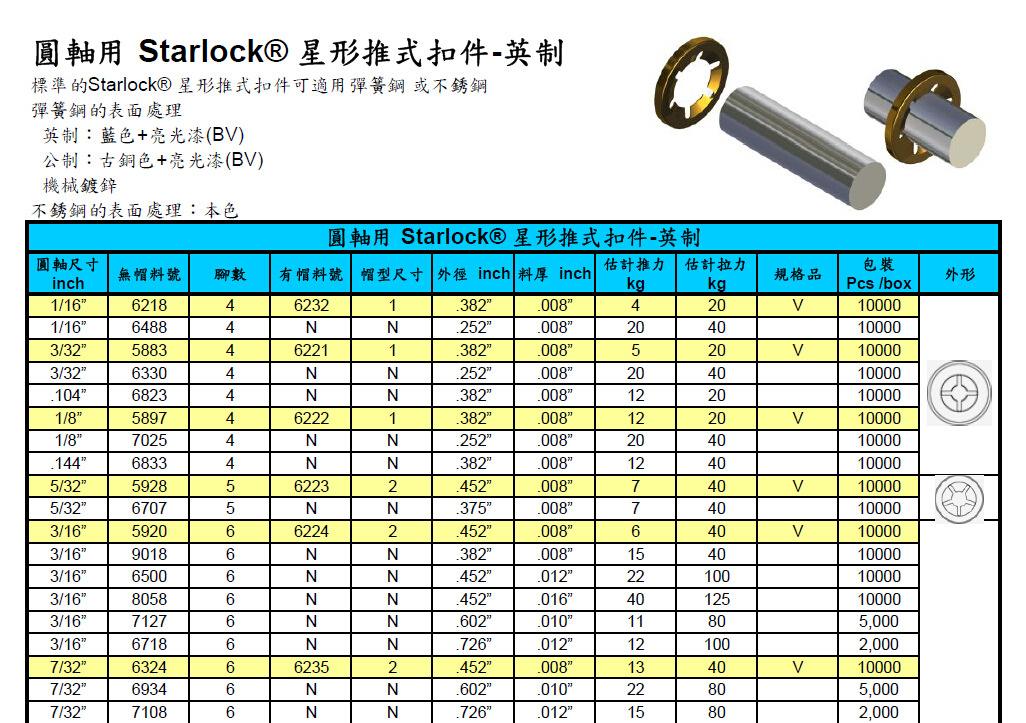

In terms of appearance and function optimization, most of StarLock's star-shaped push-type fastener series can be equipped with a cover. This detailed design not only meets the demand for refined appearance of industrial products but also plays a role in protecting the fixing device. The cover can hide the metal structure of the fastener, making the equipment surface cleaner and more attractive—this is particularly applicable to products that need to be directly exposed to users, such as home appliances and medical equipment. At the same time, the cover can isolate external dust, moisture, and impurities, preventing the fixing device from being affected by corrosion or pollution and thus maintaining its performance. To adapt to the design styles and application scenarios of different products, Starlock offers a wide range of cap styles and material options. Whether it is a simple circular cover or a customized special-shaped cover, or a wear-resistant engineering plastic material or a high-quality metal material, flexible matching can be achieved according to user needs, realizing a perfect balance between functionality and aesthetics.

The advantages of Starlock push-type fasteners go far beyond this, and their all-round performance highlights make them stand out in the market. Firstly, the products have passed RoHS certification and comply with environmental standards, allowing safe application in fields such as electronic and electrical appliances where strict control over harmful substances is required, eliminating enterprises' concerns about compliance. Secondly, they are suitable for ordinary shafts, eliminating the need for specially customized shaft components and reducing the overall production cost of equipment. In terms of functional replacement, Starlock push-type fasteners can perfectly replace traditional retaining rings, circlips, washers, cotter pins, etc., reducing the inventory management pressure of enterprises on various fasteners and simplifying the supply chain system.

More importantly, they possess core advantages such as "no thread requirement", "permanent fixing", and "elimination of tolerance accumulation". The thread-free design further reduces the complexity of processing and assembly; the permanent fixing feature ensures long-term stability of component connections; and the elimination of tolerance accumulation can improve the assembly accuracy of equipment, avoiding operational failures caused by the accumulation of tolerances of multiple components. In terms of cost and efficiency, Starlock push-type fasteners are a typical low-cost assembly solution. Not only are the material and processing costs controllable, but labor costs can also be reduced by simplifying processes. At the same time, their compatibility with automated assembly lines enables seamless integration with industrial automated production, helping enterprises achieve large-scale and efficient production.

In addition, Starlock provides customers with comprehensive technical support and services. From professional docking of engineering resources to guarantee of pressing capacity up to 60 tons, and then to in-plant customized tool design, sample development, and in-house heat treatment and finishing services, every link reflects a in-depth response to customer needs. Moreover, the "Made in UK" quality label is a strong testament to its strict quality control, adding more trust for customers when making choices.

Whether it is production enterprises pursuing efficient assembly or design teams focusing on product quality and appearance, Starlock push-type fasteners can meet their needs with comprehensive advantages. With innovative design, it breaks the limitations of traditional fasteners; with reliable performance, it safeguards the stability of equipment; and with flexible services, it adapts to diverse scenarios. It has become a high-quality choice that combines practicality and innovation in the field of industrial assembly, injecting strong impetus into product upgrading and efficiency improvement in various industries.